Eva Cosmetics manufacturing plant was brought to life in 1972, after successful 30 years, Eva took the initiative to further expand into a new state of the art manufacturing facility, equipped with the most cutting edge technology that allows us to work with a vast range of manufacturing and filling capabilities. Our operations began in the new facility in 2008.

Eva Cosmetics manufacturing plant was brought to life in 1972, after successful 30 years, Eva took the initiative to further expand into a new state of the art manufacturing facility, equipped with the most cutting edge technology that allows us to work with a vast range of manufacturing and filling capabilities. Our operations began in the new facility in 2008.

The new Eva Cosmetics Manufacturing Facility occupies a 35,000m2 area of land and it is constructed on 45% of the land. Currently our plants capacity is 385 million units/year and our resources give us the ability to further expand increasing our capacity.

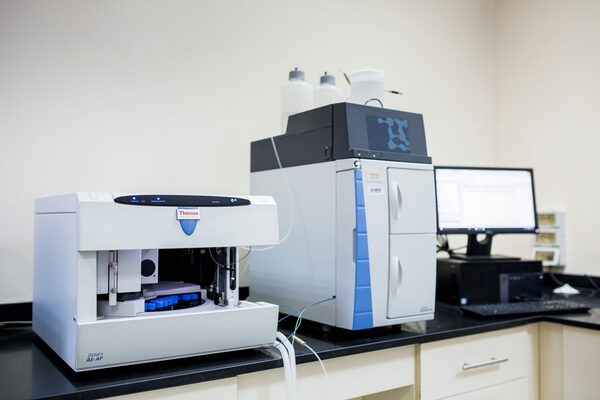

A product manufactured in EVA is more than a mix of carefully measured ingredients. It is the result of constant collaboration between highly specialized teams and high-end machinery. We have specialized teams managing each stage of the process from R &D to production to marketing and sales to ensure proper execution and follow-through. Our groups’ backbone being pharmaceutical guarantees the highest level of quality standards. We work with a vast range of mixing capabilities including: creams, lotions, liquids, semi liquids, powders, tooth paste, sticks and alcoholic products. Our filling capabilities include, Tubes, jars, sachets, pouches and bottles.

Moreover, our strategic location and sister company Akhnaton Trading ensure your perfect product reaches its final destination in pristine condition and in good time.

Over time Eva’s relentless commitment to quality portrayed through its stringent guidelines enforced by quality control and assurance specialists, has earned it a solid international reputation for being dependable and efficient. We use the Oracle System to ensure a consistent efficient performance & workflow. And we implement and improve the quality management systems and assure all the processes in the factory are verified, validated and complying with the most recent accreditations such as ISO 9001/2008. The Eva cosmetics facility operates in compliance with current good manufacturing practices (GMP and GLP) & applies the Lean Six Sigma Methodology. Our Facility has passed many inspections by some of the world’s top multinational manufacturers.